Digital

Dye sublimation

What is dye sublimation heat transfer technology?

Dye sublimation is a method of applying an image to specially coated ceramics, metals and polyester fabric.

Hard items including ceramics and metals require a special coating to accept the dye sublimation/infusible inks. However, you do not need any coating on 100% polyester items such as mouse mats and 100% polyester fabric. We stock a wide range of pre-coated sublimation imprintables and t-shirts.

Our high-quality dye sublimation inks are made especially for digital decoration and has excellent colour brightness and produces brilliantly crisp transfers.

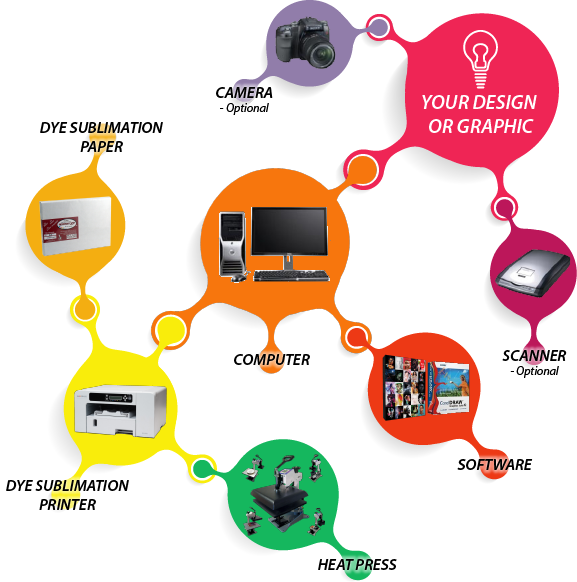

What do I need for dye sublimation?

Applications

Used dye panels retain a viewable image of the printed document, and an example of wasted dye that cannot be reused.

Alps Electric produced the first quality dye-sub printers for home consumers in the $500–$1,000 price range, bringing dye-sublimation technology within the reach of a wider audience. Now there are many dye-sublimation printers on the market starting from as low as $100, especially postcard-sized mobile photo printers.

The ability to produce instant photo prints inexpensively from a small printer has led to dye sublimation solutions supplanting traditional instant photos in some applications, such as with ID photography with a card printer.

Several corporations market desktop size units as stand-alone printers and for print kiosk and photo booth applications. Some of these units are based on generic printers. Some manufacturers, offer software development kits with their printers, suggesting that these companies hope to attract system integrators as a potential market.

Desktop size stand-alone dye-sub photo printers are also being applied by social photographers in event photography. The units' instant print ability allows photographers to produce and sell lab quality prints immediately during the event they are attending, with a minimal amount of hardware.

Dye-sublimation can also be used as an indirect printing process. Standard black and white laser printers are capable of printing on plain paper using a special "transfer toner" containing sublimation dyes which can then be permanently heat transferred to T-shirts, hats, mugs, metals, puzzles and other surfaces.

No comments:

Post a Comment