Screen printing

Screen printing is a printing technique where a mesh is used

to transfer ink onto a substrate, except in areas made impermeable to

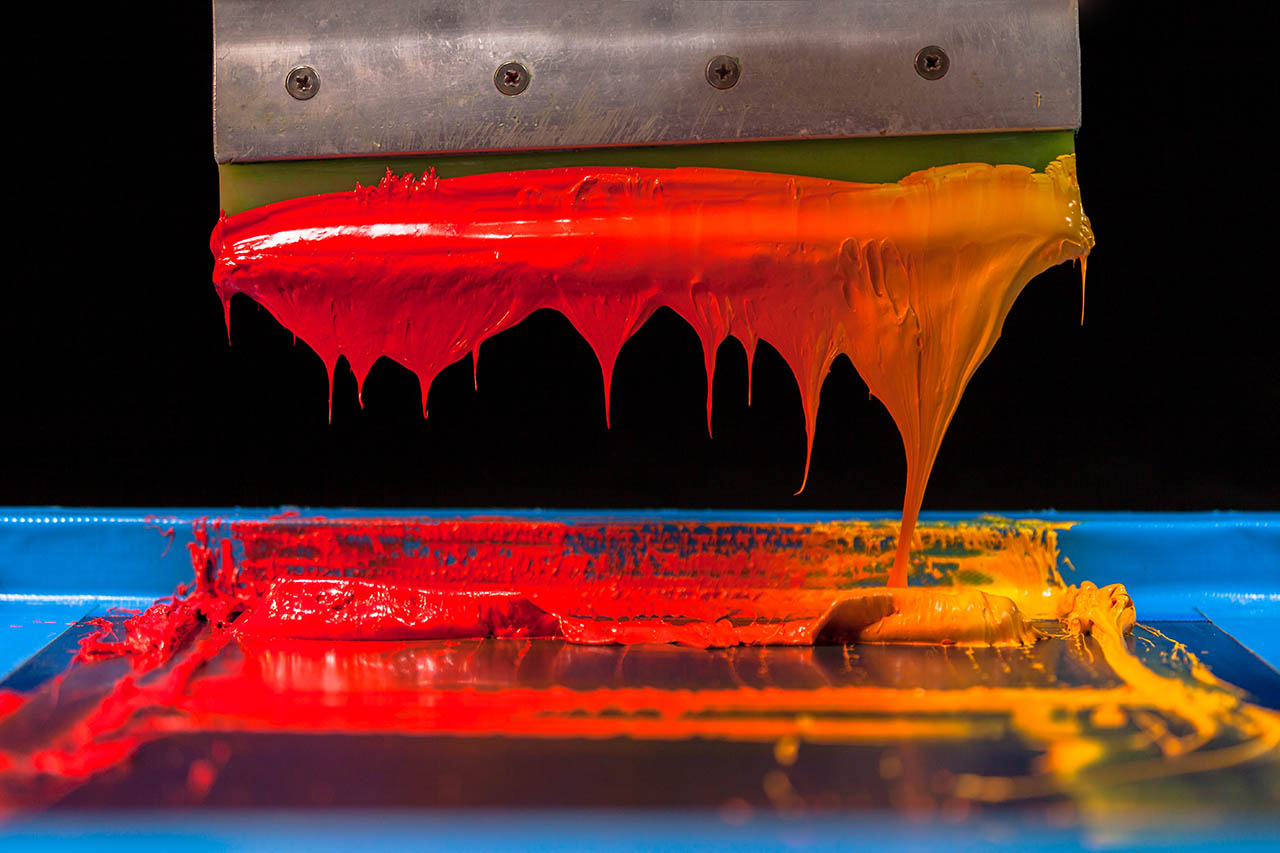

the ink by a blocking stencil. A blade or squeegee

is moved across the screen to fill the open mesh apertures with ink,

and a reverse stroke then causes the screen to touch the substrate

momentarily along a line of contact. This causes the ink to wet the

substrate and be pulled out of the mesh apertures as the screen springs

back after the blade has passed. One color is printed at a time, so

several screens can be used to produce a multicoloured image or design.

There are various terms used for what is essentially the same

technique. Traditionally the process was called screen printing or

silkscreen printing because silk was used in the process. It is also

known as serigraphy, and serigraph printing. Currently,

synthetic threads are commonly used in the screen printing process. The

most popular mesh in general use is made of polyester. There are

special-use mesh materials of nylon and stainless steel available to the

screen printer. There are also different types of mesh size which will

determine the outcome and look of the finished design on the material.

Stencilling techniques

A macro photo of a screen print with a photographically produced stencil. The ink will be printed where the stencil does not cover the substrate.

Hand-painted colour separation on transparent overlay by serigraph printer Csaba Markus

A screen must then be selected. There are several different mesh

counts that can be used depending on the detail of the design being

printed. Once a screen is selected, the screen must be coated with

emulsion and dried. Once dry, it is then possible to burn/expose the

print.

The overlay is placed over the screen, and then exposed with a light

source containing ultraviolet light in the 350-420 nanometer spectrum.

The screen is washed off thoroughly. The areas of emulsion that were

not exposed to light dissolve and wash away, leaving a negative stencil

of the image on the mesh.

Garment printing inks

- Caviar beads

- A caviar bead is a glue that is printed in the shape of the design, to which small plastic beads are then applied – works well with solid block areas creating an interesting tactile surface.

- Cracking ink

- Cracking ink effect is when the ink produces an intentional cracked surface after drying. The primary cause of unintentional cracking of ink is from the ink not curing fully.

- Discharge inks

- Discharge inks use Zinc Formaldehyde Sulfoxylate to activate the dye in fabric to discharge from the originating fabric. Discharge inks are available in clear or colors. Cons of using discharge inks is that the process only works properly on dark fabrics that have a content of 100% cotton. Fabrics with under-dyes and fabric blends will discharge their dye to different degrees. The fumes resulting from the application and curing are pungent and strong ventilation and a face mask are commonly needed to relieve exposure. Pros to this process is that discharge is especially effective for distressed prints and under-basing on dark garments that are to be printed with additional layers of plastisol. It adds variety to the design and gives it that natural soft feel.

- Expanding ink (puff)

- Expanding ink, or puff, is an additive to plastisol inks which raises the print off the garment, creating a 3D feel and look to the design. Mostly used when printing on apparel.

- Flocking

- Flocking consists of a glue printed onto the fabric and then flock material is applied for a velvet touch.

- Foil

- Foil is much like flock, starting with an adhesive glue or plastisol ink base layer. Foil is finished by applying a thin sheet of reflective/mirror like material on top of the screened base, then heat pressed to set. The foil substrate does not adhere to non-screened areas of the design, and the balance of the foil sheet is discarded.

- Glitter/shimmer

- Glitter or shimmer ink is when metallic flakes become an additive in the ink base to create this sparkle effect. Usually available in gold or silver but can be mixed to make most colours.]

- Gloss

- Gloss ink is when a clear base laid over previously printed inks to create a shiny finish.

- Metallic

- Metallic ink is similar to glitter, but smaller particles suspended in the ink. A glue is printed onto the fabric, then nano-scale fibers applied on it. This is often purchased already made.

- Mirrored silver

- Mirrored silver is a highly reflective, solvent-based ink.

- Nylobond

- Nylobond is a special ink additive for printing onto technical or waterproof fabrics.

- Plastisol

- Plastisol is the most common ink used in commercial garment decoration. Good colour opacity onto dark garments and clear graphic detail with, as the name suggests, a more plasticized texture. This print can be made softer with special additives or heavier by adding extra layers of ink. Plastisol inks require heat (approx. 150 °C (300 °F) for many inks) to cure the print.

- PVC and phthalate free

- PVC and phthalate free is relatively new breed of ink and printing with the benefits of plastisol but without the two main toxic components. It also has a soft texture.

- Suede ink

- Suede ink is a milky coloured additive that is added to plastisol. With suede additive you can make any color of plastisol have a suede feel. It is actually a puff blowing agent that does not bubble as much as regular puff ink. The directions vary from manufacturer to manufacturer, but generally up to 50% suede can be added to normal plastisol.

- Water-based inks

- these penetrate the fabric more than the plastisol inks and create a

much softer feel. Ideal for printing darker inks onto lighter coloured

garments. Also useful for larger area prints where texture is important.

Some inks require heat or an added catalyst to make the print

permanent.

No comments:

Post a Comment